Industrial CT is the abbreviation for Industrial Computed Tomography technology. The imaging method is to perform tomography on the work piece and perform digital processing to give a two-dimensional tomographic image that truly reflects the internal structure of the work piece. After the three-dimensional image is processed, a three-dimensional model is obtained through image processing according to a certain image reconstruction algorithm. The model can intuitively reflect whether the work piece has defects, the exact location of the damaged defects, the size, and distribution and shape of its internal structure. An industrial CT system generally consists of a ray source, front and rear collimators, detectors, mechanical scanning control mechanisms and computer systems. Industrial CT has become an indispensable technical support in China’s aerospace, military industry, manufacturing, new materials and other fields.

At present, the commonly used detectors mainly use Amorphous silicon (A-Si) flat panel detectors.Its image sensors are composed of photo diode arrays with two-dimensional pixel structure, each pixel contains a thin film transistor (TFT) and a photo diode. These two components are made of amorphous silicon material, which is formed on a large-area glass substrate by a photolithography process. The process is mature and stable, and the price is low. At the same time, the amorphous silicon material has strong radiation resistance to X-rays. Suitable for industrial high-dose imaging applications.

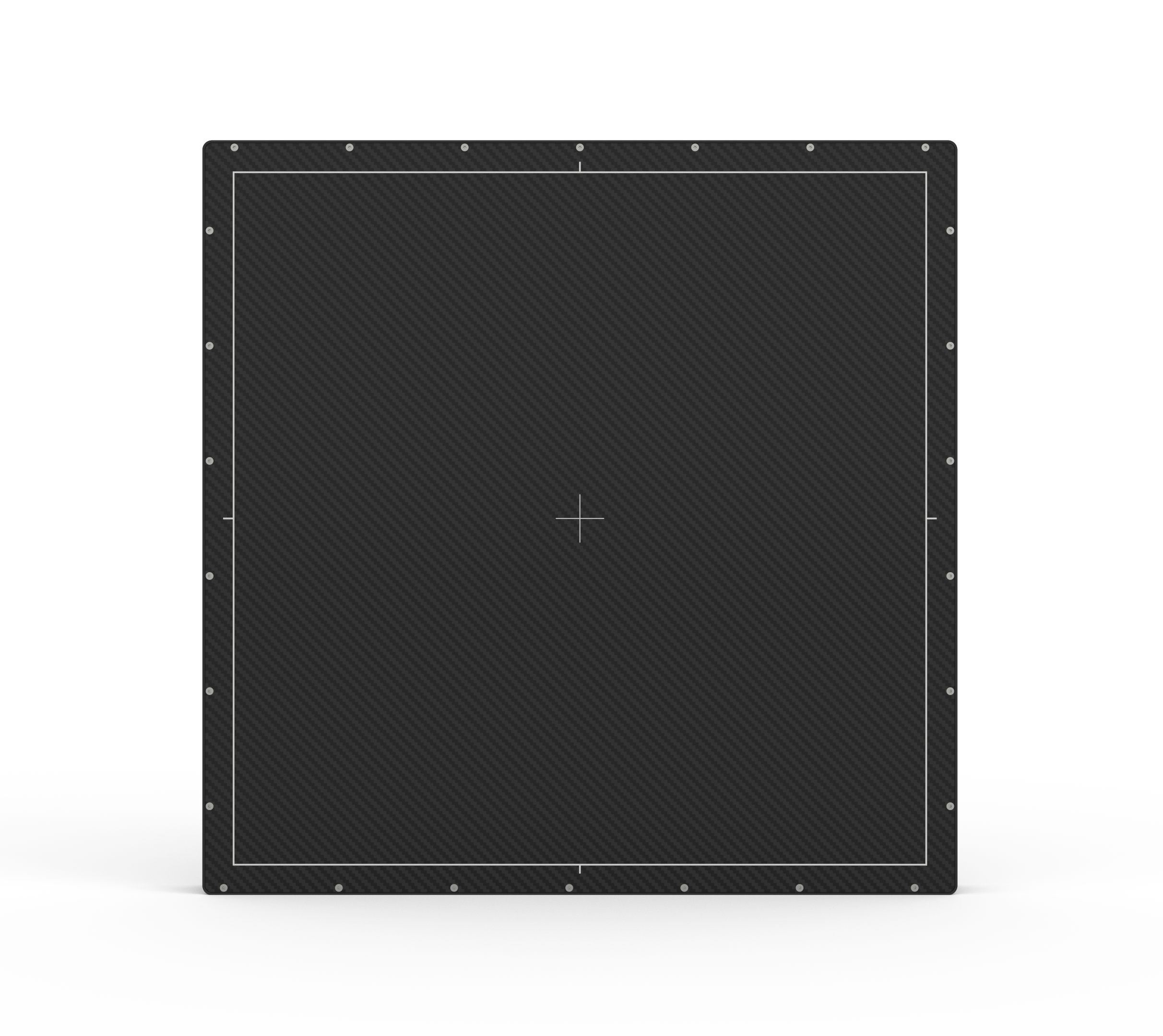

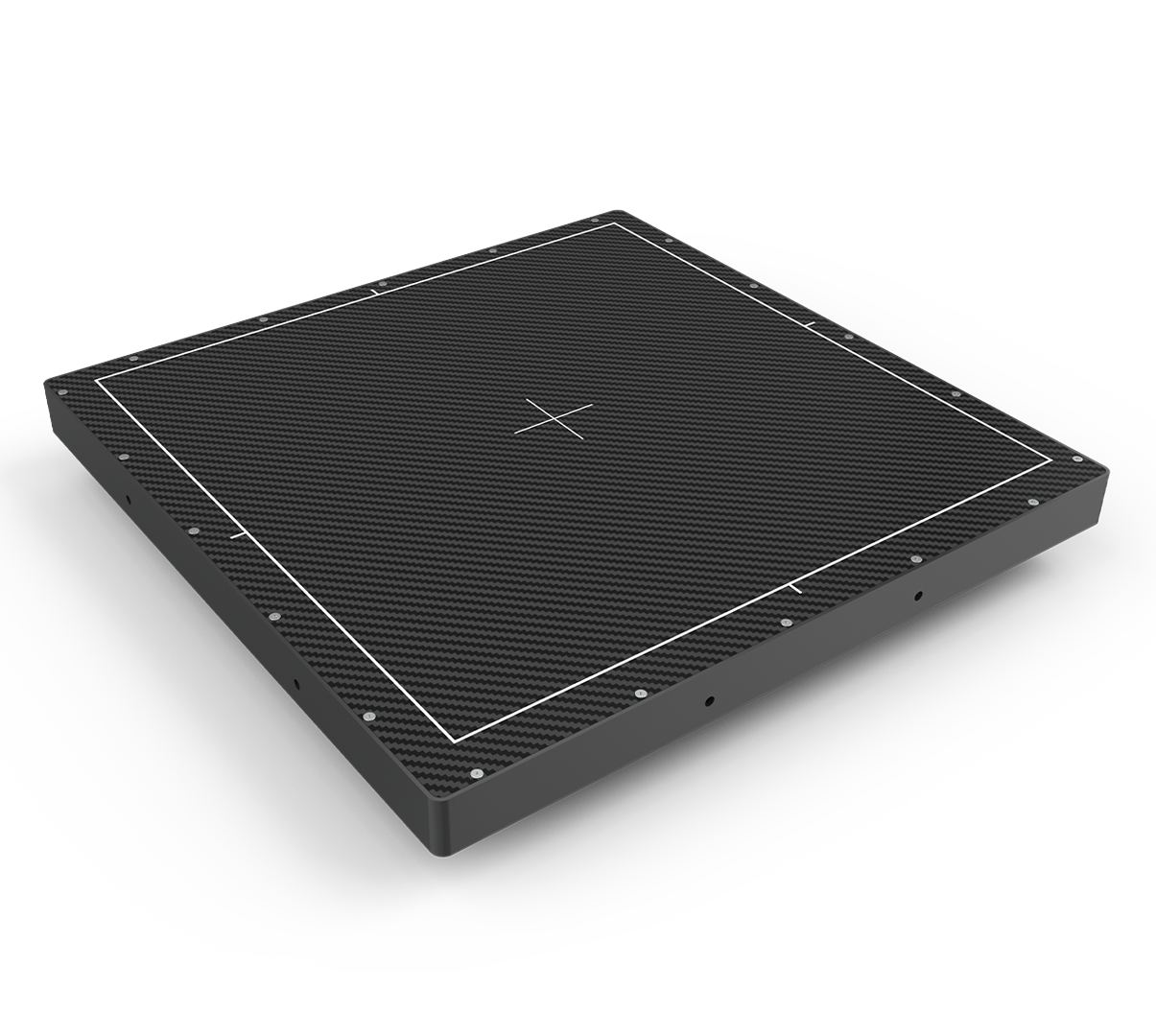

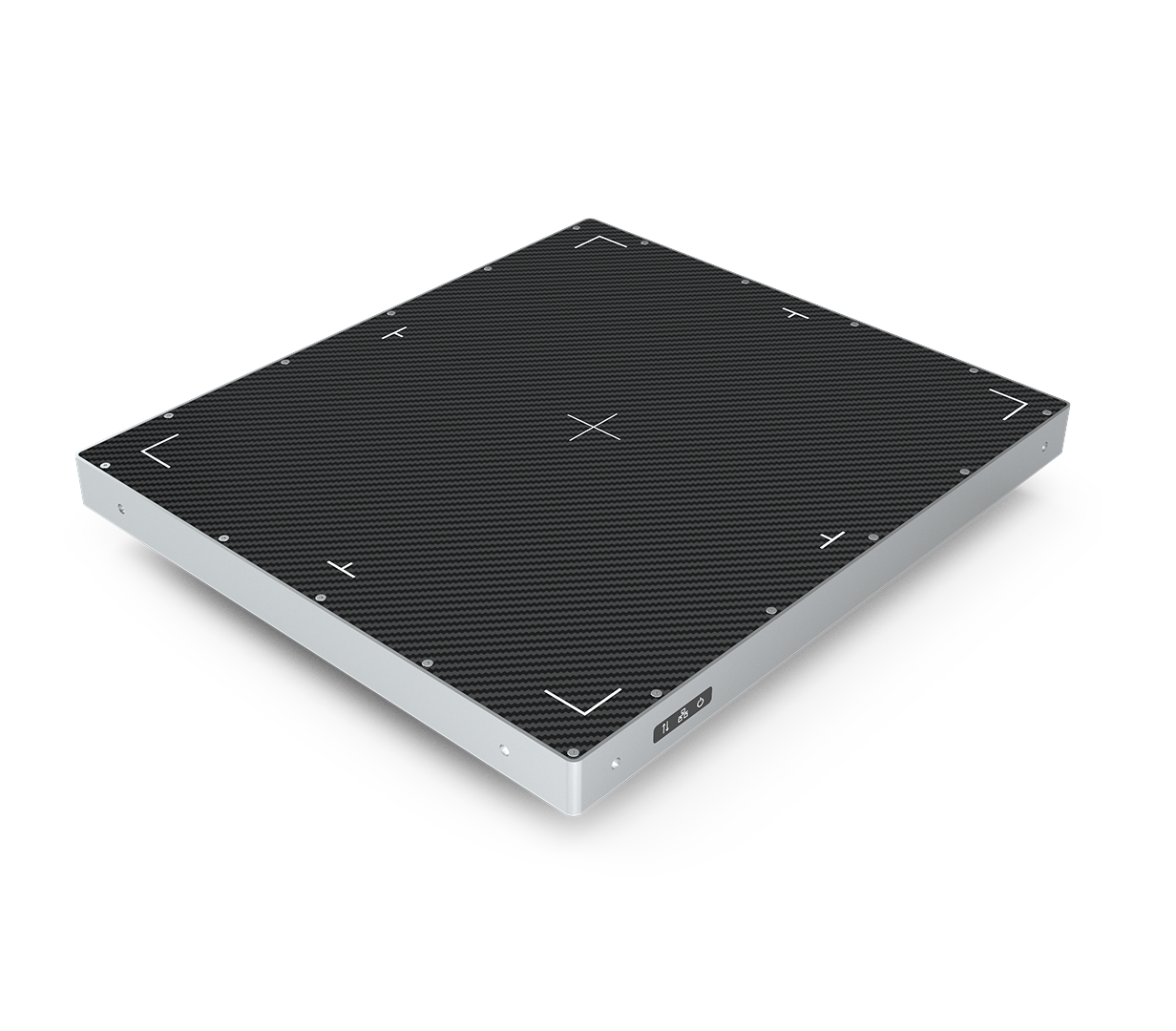

The Whale series fixed flat panel detector independently developed and designed by Haobo is specially developed for industrial CT application scenarios. It is a fixed low noise dynamic flat panel detector. The front panel of the detector adopts amorphous silicon (a-Si) material technology. The flat panel detector based on amorphous silicon material technology has the characteristics of high image quality, large dynamic range and wide range of terminal applications. This product is designed to

Fixed style, with multi-gain program-controlled adjustment gears, this function makes it suitable for both high-sensitivity applications and large dynamic range scenarios.

Hardware product recommendation

Post time: Jul-19-2022