The rapid development of microelectronics technology, especially the rise of smart phones in recent years, requires miniaturization of packaging and high-density assembly. Various new packaging technologies are constantly improving, and the requirements for circuit assembly quality are getting higher and higher. With the integration of the SMT process, new inspection technologies are constantly innovating. The application of automatic X-ray inspection technology has realized the inspection of invisible solder joints, such as BGA, etc. Malfunction found.

X-ray inspection technology provides an effective inspection method for improving the "one-time pass rate" and striving for the goal of "zero defect".

(1) The coverage rate of process defects is as high as 97%. The defects that can be inspected include: virtual soldering, bridging, tombstones, insufficient solder, air holes, missing devices, etc., and hidden devices such as BGA and CSP solder joints can also be inspected

(2) High test coverage, can check what can not be observed by the naked eyes online. For instance; if PCBA is judged to be faulty, or suspected that the inner wiring of PCB is broken, the X-ray can quickly detect it.

(3) The preparation time for the test is greatly shortened

(4) Defects that cannot be reliably detected by other testing methods can be observed, such as: virtual welding, air holes and poor molding

(5) Only one inspection is required for double-sided and multi-layer boards (with layering function)

(6) Relevant measurement information can be provided to evaluate the production process, such as solder paste thickness, amount of solder under solder joints, etc.

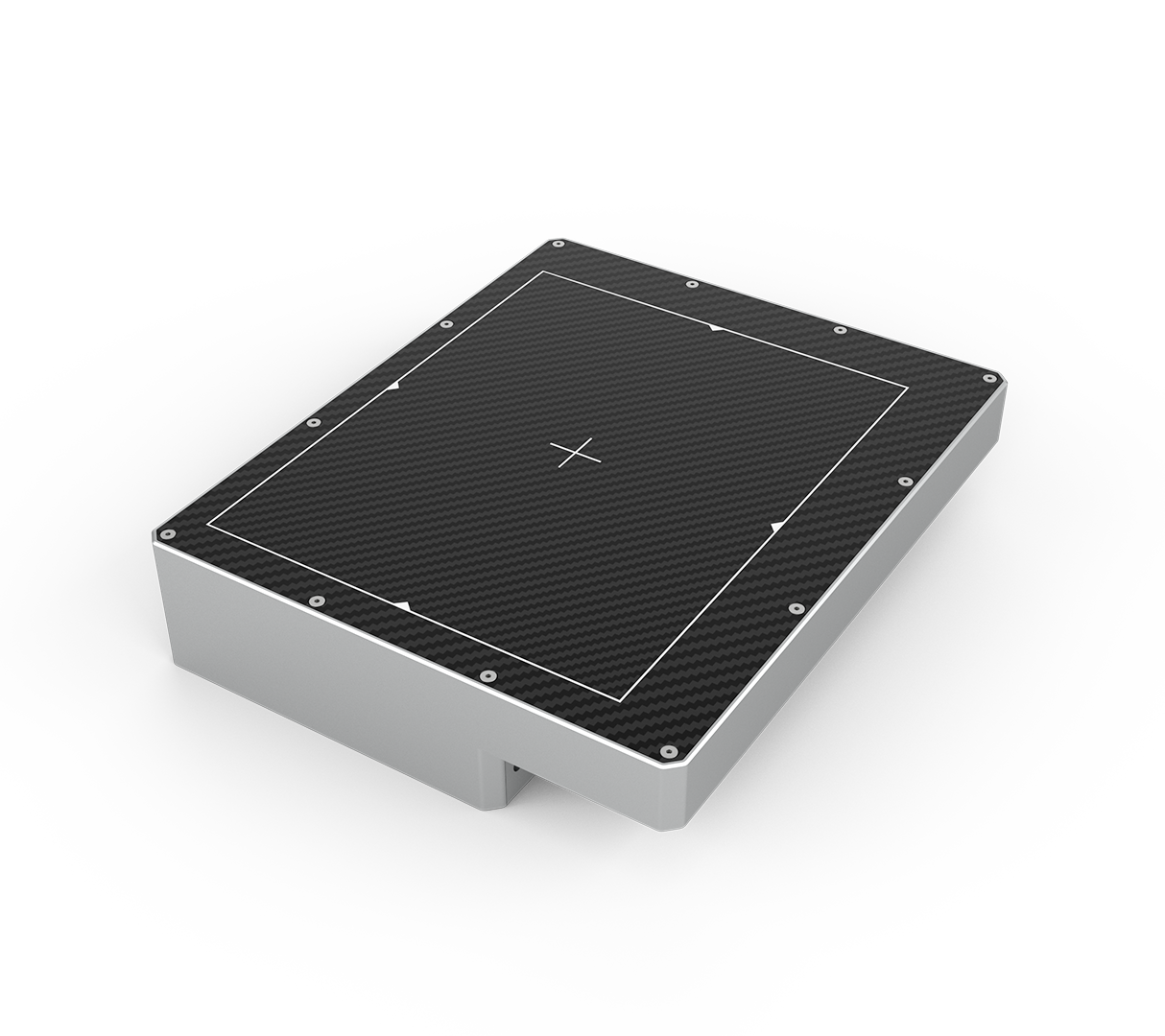

The X-Panel 1613a FDI series X-ray flat panel detector independently developed and designed by Haobo is specially developed for the application of industrial SMT welding inspection equipment. It is a 16*13cm real-time imaging amorphous silicon dynamic flat panel detector. The frame rate of image acquisition can reach 30fps, and it has the characteristics of high image quality, large dynamic range and high imaging contrast. This fixed detector adopts industrial-grade standard design, is stable and durable, and has the characteristics of high radiation resistance, wide environmental adaptability, and high reliability. The SDK software development kit provided by Haobo supports Windows and Linux operating systems, allowing you to easily configure parameters, calibrate and capture images of the detector.

Hardware product recommendation

Post time: Jul-19-2022