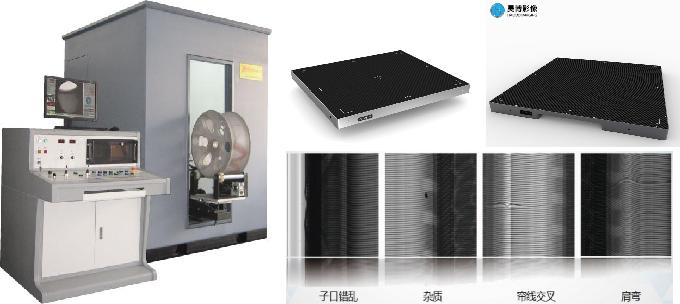

Die castings are widely used in many fields of industrial production, especially in automobile and aerospace manufacturing, because of the advantages of low cost, one-time forming, and the ability to manufacture large parts with complex structures. During the casting process, some die castings will have defects, such as oxidized impurities, bubble holes, shrinkage porosity, cracks, etc. These defects affect the performance and service life of die castings, and can cause potential hazards in use, especially in manufacturing industries such as automobiles and aerospace. The impact of these potential hazards is even more serious.

In order to ensure the quality of die castings, manufacturers need to carry out scientific and rigorous testing of die castings. There are many detection methods for die castings. For some internal defects that cannot be detected by ordinary methods, X-ray non-destructive testing is ideal. It can detect the internal structure and mechanical properties without damaging the inspected object. This makes many defects clear at a glance, and has the characteristics of being intuitive and convenient for qualitative and quantitative analysis of defects.

The Whale series fixed flat panel detector independently developed and designed by Haobo is specially developed for the application scenarios of industrial die casting inspection equipment. It is a fixed low noise flat panel detector. The front panel of the detector is made of amorphous silicon (a-Si) material technology, a flat panel detector using amorphous silicon material technology, which has the characteristics of high image quality, large dynamic range and wide range of terminal applications. The fixed-style design has multi-gain programmable adjustment gears, which makes it suitable for both high-sensitivity applications and large dynamic range scenarios.

Hardware product recommendation

Post time: Jul-19-2022